USA Trains: Hudson - Modifications & Repair page:

(Click here for USA Trains: Hudson - Photo and Video Page)

Model Overview:

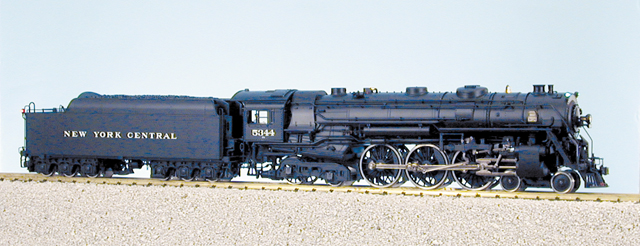

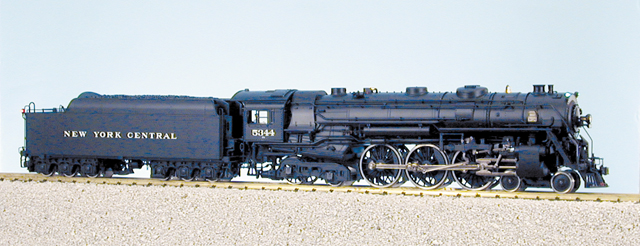

USA Trains first steam locomotive.

________________________________________________________________________________

USA Trains - Hudson - Repair/Modifications:

Modifications/Topics list:

USA Trains - Hudson: (Model info)

________________________________________________________________________________

10/19/2010

Engine shorting out / Running loud - (due to motor failure):

USA Hudson was presented to me for repair with the symptom of running loudly with shorting only while moving. The problem turned out to be a failed motor due to the friction bearing on the worm gear side of the motor had worn to the point where the motor armature was getting far enough out of alignment to physically impact the motor magnets.

(I

now stock replacement motors with higher performance and with lifetime bearings.

Please email me at:  if you are in need of one of these motors as USA Trains has been out of stock on

these for quite some time.)

if you are in need of one of these motors as USA Trains has been out of stock on

these for quite some time.)

|

|

|

||

If you own this engine (or the USA Big Boy) I would recommend taking the time to put a drop (not a lot!) of good quality oil on each end of the motor bearings. Keeping the bearings lubricated should go a long ways to delaying this sort of wear and eventual failure.

See the video below for example of this condition:

-

67MB/7000kbs -

YouTube 1080 HD

-

67MB/7000kbs -

YouTube 1080 HD

(Note: if the .mp4 video skips, right click on the link and select "save target as" and save it to your local drive, then play it.)

__________________________________________________________________________________

11/09/2010

Drawbar modification (Tender comes uncoupled when backing):

Even under a relatively light load, the tender has the tendency to come uncoupled. This is because the drawbar spring allows the end of the drawbar to drop fairly easily.

|

|

|||

In order to fix this, I replaced the original spring with five washers.

|

|

|

||

__________________________________________________________________________________

11/09/2010

Back-end of Engine Sagging (Factory trailing truck spring too weak):

Every USA Hudson I've seen has had an uneven stance with the boiler sagging too far down in the back. As can be seen in the videos below this is because the trailing truck spring used by the factory is not strong enough to help hold up the weight of the rear of the engine.

- Video - 0:29 mins - Example of engine sagging with original USA Trains spring

- 26MB/7000kbs - YouTube 1080p HD

(Note: if the .mp4 video skips, right click on the link and select "save target as" and save it to your local drive, then play it.)

To fix this problem I replaced the original spring with a stronger one. Proper attention needs to be paid to finding the right amount of additional strength. Too strong a spring will take unneeded weight off the drivers, lowering it's tractive effort. The below photos show the new spring and the video shows the result.

|

|

|

|

|

- Video - 0:16 mins - Example of engine now level with new replacement spring

- 14MB/7000kbs - YouTube 1080p HD

(Note: if the .mp4 video skips, right click on the link and select "save target as" and save it to your local drive, then play it.)

__________________________________________________________________________________

11/09/2010

Power pickup problems: Wheel power pickups not making contact with wheels:

Below is an example of an engine with power pickup problems due to wheel power pick-ups not making contact with the backs of the drivers. In this case the problem had two causes: 1) the plastic brush holder was ovaled out and worn causing the brush to be at enough of an angle as to not slide properly back and forth and 2) the brushes were worn.

|

|

|

|

|

- Video - 0:16 mins - Example of engine with power pickups not making contact with the drivers

- 14MB/7000kbs - YouTube 1080p HD

(Note: if the .mp4 video skips, right click on the link and select "save target as" and save it to your local drive, then play it.)

To fix, the brushes and plastic brush assemblies needed to be replaced.

|

|

|

||

Next, the brush and assembly need to be removed from the small screw connector plate. To do this, use a pair of pliers to grab a hold of the brush and use your hand to unscrew the screw connector plate (rotate the plate to the left).

|

|

|

||

Next take the new brush and assemble as the last photo above shows. Make sure the brush slides in and out smoothly. You may need to take a small philips head screw driver to clean up the back side of the brush assembly to remove any excess plastic. Just fit against the hole (it should be bigger than the hole and not fit inside) and twist a few times and let it scrape off the edge. (You may want to add a little bit of oil to lubricate.) Once you've confirmed it slides smoothly, install the new brush and assembly by reversing the process above.

__________________________________________________________________________________

11/09/2010

Adding a functioning drop Kadee 822 coupler to the front pilot:

A functioning #1 scale coupler can be installed to replace the original non-functioning one. A Kadee 822 coupler needs to be modified as seen in the below photos. In addition the coupler drop back plate needs to be modified as shown in the last two photos. (This back plate will limit how far down the coupler will drop). Use a couple of needle nose pliers to bend.

|

|

|

|

|

|

|

Here is the final product:

|

|

|

|

|

|

|

|

|

|||||

__________________________________________________________________________________

11/09/2010

Driver axle suspension doesn't have proper range of motion / sticking in frame:

I discovered on my engine the rear driver axle (axle #3) would not move up and down properly (as would axle #2). Further inspection revealed the frame on the engineer's side where the axle/suspension block slid in was too narrow. (Improper casting mold at the factory) To fix the issue, the sides of the frame needed to be filed down to allow proper travel. (If your engine needs this try to ensure you take the proper amount of material off each side.)

|

|

|||

__________________________________________________________________________________

11/09/2010

Installed MTH Protocoupler on tender:

Photos of the functioning MTH Protocoupler installed on my Hudson's tender. The rear coupler can now be remotely opened via the rear coupler button my DCS remote.

|

|

|

|

|

_________________________________________________________________________________

11/21/2010

USA Trains does a very nice job on the coal loads used in it's steam engines. Due to damage, I was required to redo the coal load and decided to take the opportunity to improve on the height and form originally used. (The original loads are very flat and from the side have no mound visible.)

The first step to add coal is to remove the coal load from the tender and then brush & apply the desired adhesive (in this case 50% Mod Podge 50% Water with few drops of rubbing alcohol) over all the surfaces you want covered with coal.

Photos of Aristocraft Vanderbuilt tender

|

|

|||

Next, place the coal load over a box and sprinkle the coal on and add enough to create the desired form and height.

|

|

|||

Then using a dropper, drip additional adhesive over the entire top surface of the coal load. Be sure to add enough so it works it's way to the bottom. (You need to try and find a right balance between too little and too much.) Let the glue dry for 12-24 hours and be careful to not tip or shake.

|

|

|||

Here is the finished product.

|

|

|||

__________________________________________________________________________________